- AdventHealth

The world of 3D printing has evolved tremendously over the years, and there have been many different versions of this device since the origins that can be traced back to 1986. While there are multiple uses for this invention, the Prototype Lab at Nicholson Center offers great advantages to help throughout the product development journey.

Key Advantages:

- AdventHealth Nicholson Center is one of the leading surgical education centers in the world, with a specific focus and expertise in clinical education. With this level of expertise, you are working with a team who will provide the industry knowledge as well as the skill to develop the specific product you are looking for.

- The clinical expertise that our team brings is pivotal in the early stages of development. We will collaborate with you in a brainstorming session to speak to your various needs concerning the product. We sit with you, and create a specific plan based on your desires to bring the product to life.

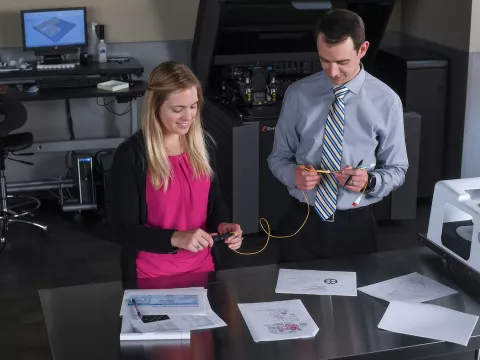

- The Prototype Lab is an innovative space for physicians, researchers, engineers and other health care professionals to bring their ideas for development of medical devices from concept to functional prototype. We have engineers in-house that use the latest technology in 3D CAD modeling and 3D printing, to help inventors develop, test and refine their latest ideas to improve clinical outcomes.

- The ability to immediately test the product on tissue is an essential advantage to using the Prototype Lab at the Nicholson Center. Many product developers will have the product, and must then find the lab to test it in. Here at Nicholson Center our clients have the comfort in knowing they can take their products from the printer to the lab for immediate testing, which keeps the development journey moving at a steady pace.

Our team…

Engineers in the Prototype Lab accelerate the design process by bridging the product development and training gap between industry and frontline clinicians. At the Nicholson Center the engineering process pairs the quality of traditional methods with the speed and innovation that today’s technology provides. The engineering team works closely with physicians and clinical staff to brainstorm and create devices that will enhance patient outcomes.

Our engineers take the initial concept (“napkin sketch”), brainstorm ideas, and do a preliminary prior art and patent search. From there, we begin 3D modeling your idea and send you screenshots or 3D PDF documents for viewing anywhere. After a final design is evaluated and selected, the model is sent to the in-house 3D printer. Our Connex3 polyjet printer has the ability to print over 1,000 materials including rigid plastic, flexible rubber, transparent, full color, and any combination for a functional prototype! The fast and precise process of 3D printing allows the inventor to hold a real-life device in their hands for evaluation. After initial assessment, we can update any design changes and re-print if needed. The inventor then has the unique opportunity for immediate testing of their device on tissue in the same building.

Additionally, our work extends from instrumentation to personalized medicine. In the lab, we can 3D print patient anatomy converted from a CT or MRI scan to be used during patient consultation, surgical planning, and as a reference throughout a procedure. Having these forward-looking capabilities in-house provides physicians with an additional pre-surgery planning tool leading to improved patient outcomes. Lastly, the team can help develop specialized educational training devices. These devices can be used in courses to teach specific procedures or for training on particular machines.

Jodi Fails, B.S., is a trained Biomedical Engineer and leads the Prototype Lab at the Nicholson Center. She has over 5 years’ experience in medical device and simulation prototype design and development. She has worked on several projects taking concepts to functional prototypes which are tested by end users and eventually commercialized via companies in the field. She played a key role on the 2017/2018 Des Cummings Innovator Award winning teams and is also an inventor on US Patent Application Publication US20180310807. Her background expertise includes mechanical engineering skills, 3D CAD modeling, silicone mold modeling, and polyjet 3D printing. Jodi’s educational background includes a B.S. in Biomedical Engineering with a major in Biomechanics from Marquette University in Milwaukee, WI.